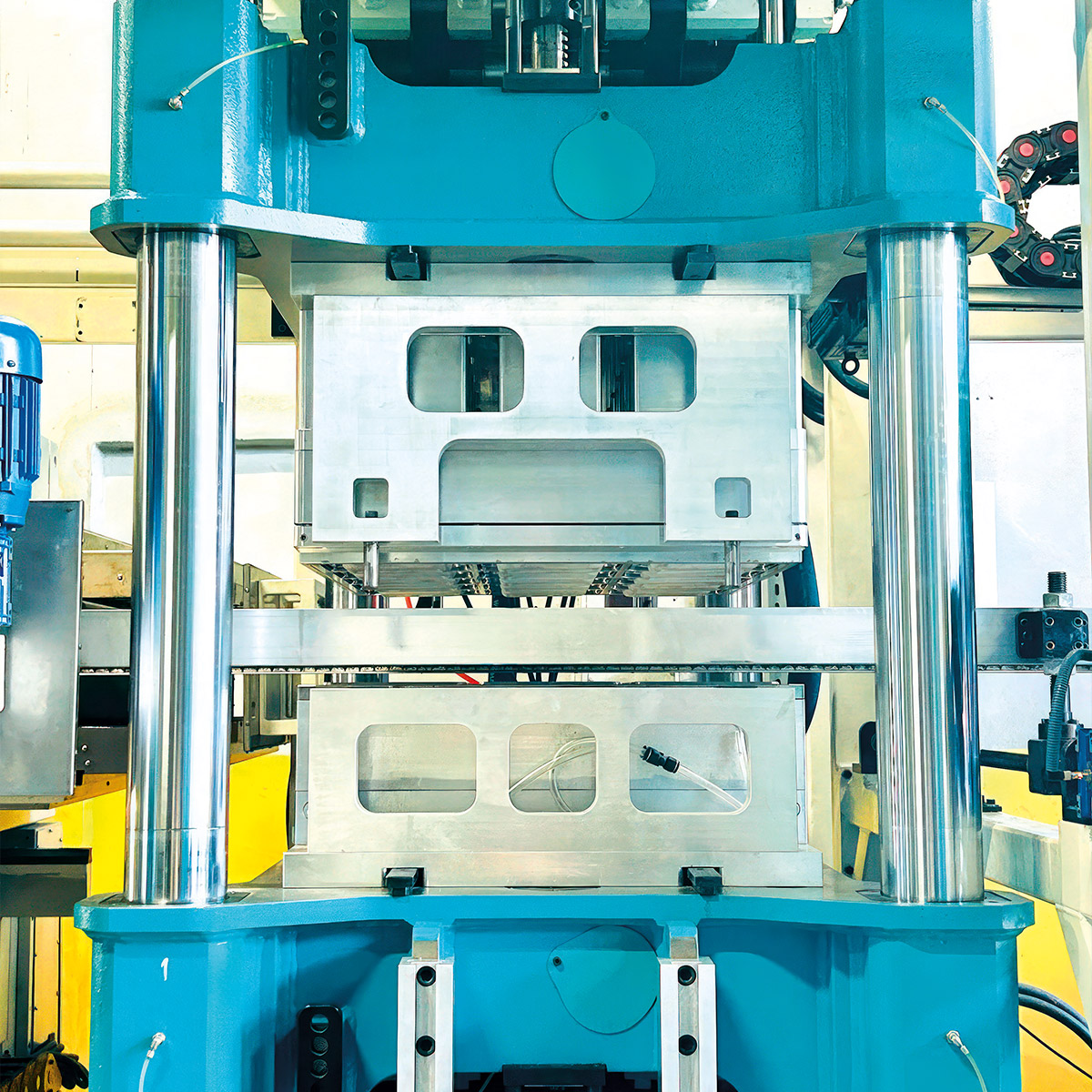

With our state-of-the-art equipment and expert team, we

deliver the best quality products to our customers.

Namık Kemal Mah. 120. Sk. No:16 Esenyurt, İstanbul

Copyright © 2024 Omni Makina. All rights reserved. Design Sude Ajans

WhatsApp us