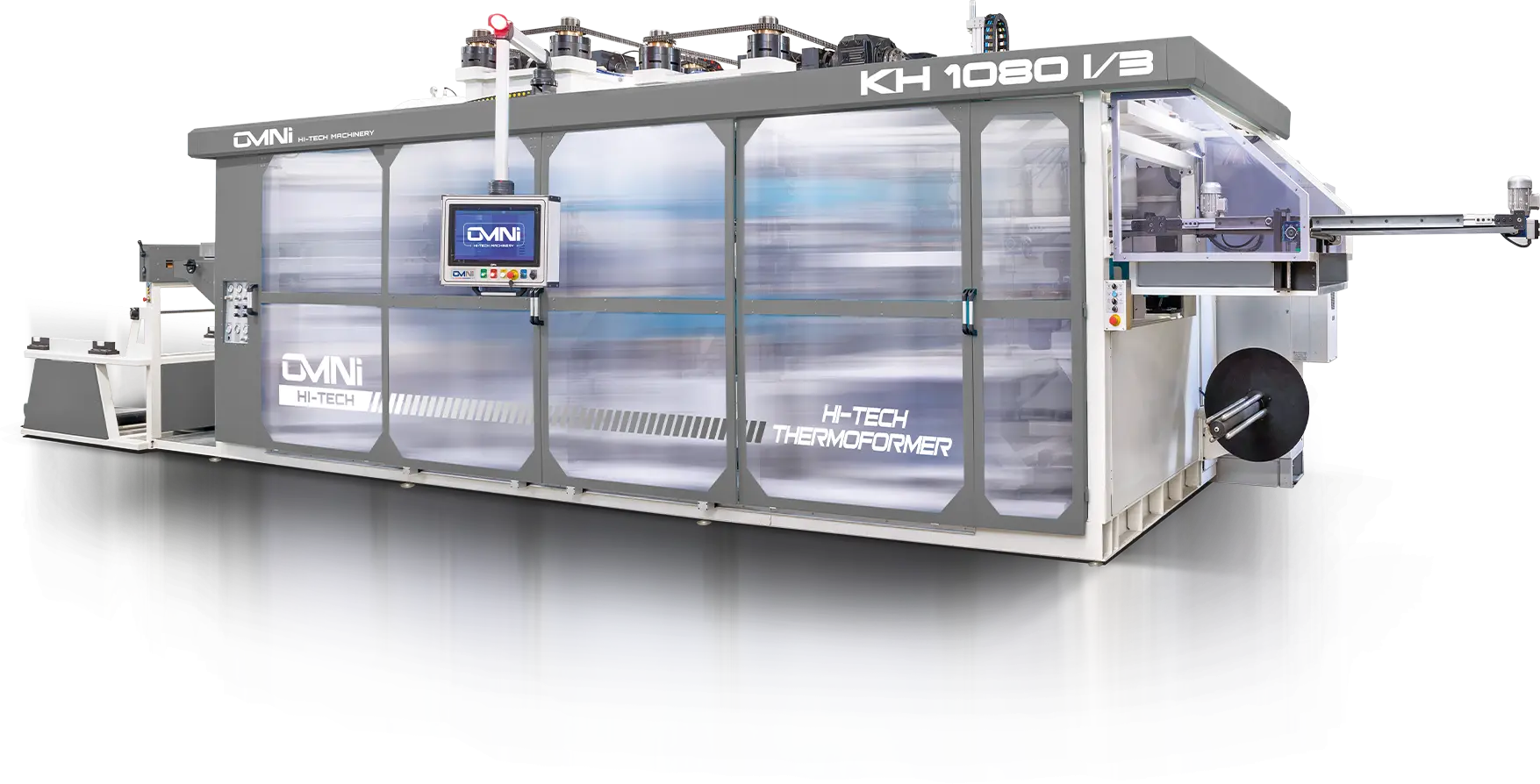

As OMNİ MACHINERY, we provide customized and high-quality mold solutions for thermoforming machines.

Utilizing CNC Machining Center and 3D Design technologies, we offer our customers molds equipped with the latest technology. Our company aims to be a pioneer in the industry with its research and development-focused approach. We specialize in developing custom designs to meet customer needs. Along with in-mould cutting, we provide fast and efficient solutions to our customers’ demands.

With our state-of-the-art equipment and expert team, we

deliver the best quality products to our customers.

Design that allows precise cutting, especially in large and multi-cavity molds, with a maximum mold width of 1060 mm

Long-lasting use of the chain thanks to specially designed chain rails and chain arms (chains last at least 2 times longer than average production times)

Possibility of up to 160mm deep and high molds (Mold life is longer since the plug asist is in the servo center)

Advantage of using mold frame at the same time in molds with servo plug

Easy forming in multi-cavity molds with a 2.5” high-pressure air-controlled MAC valve (Allows for higher cycle operation).

With precise parallel adjustment, the risk of deviation in parallelism is minimal (0.02mm).

Ability to position with 0.02 mm precision in mold recipe values with forward and reverse servo motor and screw shaft for cutting and stacking.

Namık Kemal Mah. 120. Sk. No:16 Esenyurt, İstanbul

Copyright © 2024 Omni Makina. All rights reserved. Design Sude Ajans

WhatsApp us

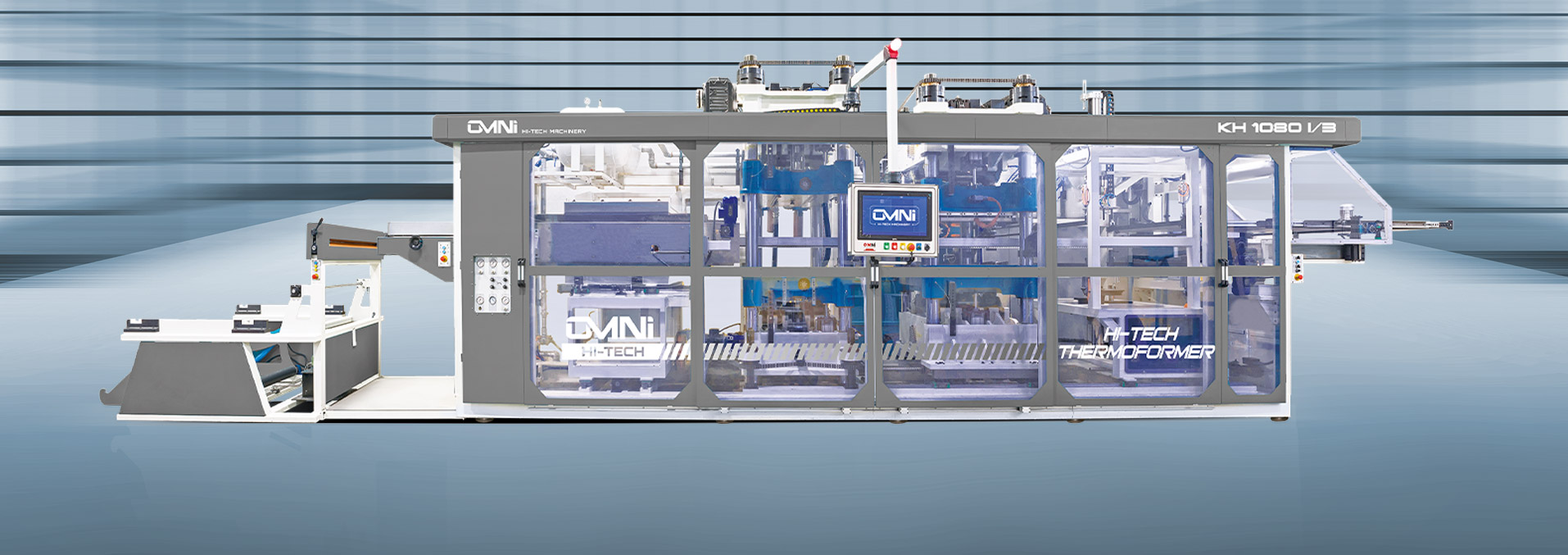

A more comfortable heating process without the need for preheating, with a total of 145 kW upper heater, including 12 zones vertically and 16 zones horizontally.