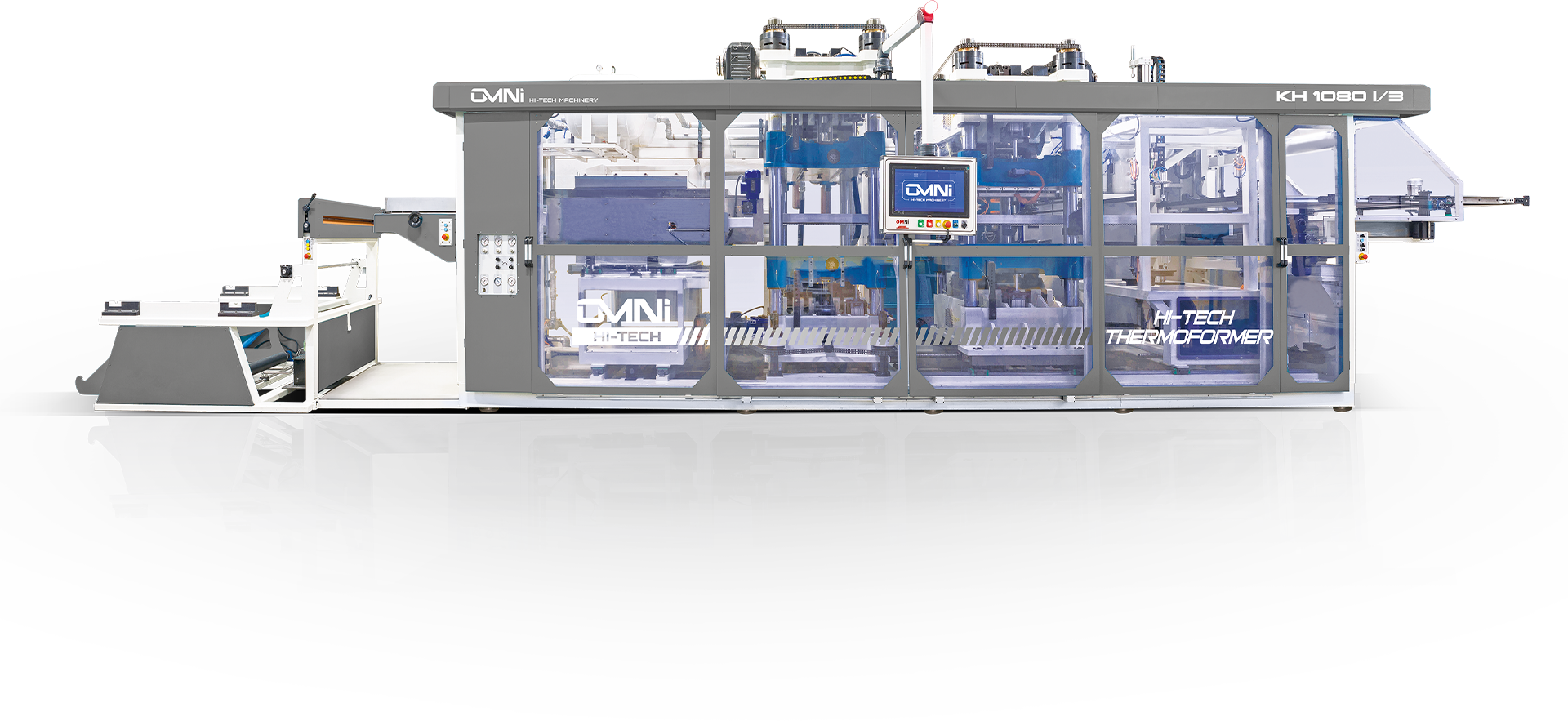

Ideal For Large And Multi-Cavity Moulds

Design that allows precise cutting, especially in large and multi-cavity molds, with a maximum mold width of 1080 mm

Long-Lasting Chain Friendly

Long-lasting use of the chain thanks to specially designed chain rails and chain arms (chains last at least 2 times longer than average production times)

Advantage Of Installing High-Height Molds

Possibility of up to 160mm deep and high molds (Mold life is longer since the plug asist is in the servo center)

When The Servo Plug Is Active, The Mold Frame Is Also Active

Advantage of using mold frame at the same time in molds with servo plug

High Forming Efficiency

Easy forming in multi-cavity molds with a 2.5” high-pressure air-controlled MAC valve (Allows for higher cycle operation).

Easy Parallel Adjustment

With precise parallel adjustment, the risk of deviation in parallelism is minimal (0.02mm).

Long-lasting blade advantage in cutting blades with 0.02 mm minimum parallelism system.

Cutting And Stacking With Forward And Reverse Servo Motor And Screw Shaft

The back and forth positioning in the cutting and stacking stations is done with a servo motor and ball screw, which enables the positioning with a precision of 0.02 mm at the mold recipe values.

Powerful Cooling In The Cutting Station

Powerful cooling advantage with dual-way cooling input and output in the cutting station eliminates heating risk in blocks

2. 5 Tons Of Hydraulic Roll Lifting Power

Advantage of tying 2 x 2.5 tons of rolls.

Screen interfaces are designed to provide convenience to the user. Possibility of digital adjustment of machine forming air pressure via the monitor.

Gap Precision In Shears Is 0.03 mm

Gap precision of 0.03 mm in shears at cutting stations ensures rigidity in cutting. Clearance accuracy in scissors is 0.03 mm. The gap precision of the scissors at the cutting stations is 0.03 mm, which provides rigidity in cutting.

Mechanical components are manufactured in accordance with ISO tolerance standards.

FAG and SKF brands are used in the bearings.

The welding method applied at stations ensures longevity in presses. High standards of welding method are applied in the stations, ensuring long life in the presses.

All parts are manufactured with specially selected high qualified steels and special heat treatment processes.

The cooling system has a water flow warning with a flow switch.

With the special design to protect the vacuum system, the system gives a warning and any water leaks in the molds are removed from the system before they even reach the vacuum pump.

|

Techinal Features |

KH 1080 I/3 | KH 900 I/3 | KH 1080 I/2 | KH 900 I/2 | |

|

Maximum Mold Area |

1080 X 770 mm | 900 X 700 mm | 1080 X 770 mm | 900 X 700 mm | |

| Maximum Forming Area | 1060 X 765 mm | 880 X 695 mm | 1060 X 765 mm | 880 X 695 mm | |

| Maximum Product Height | 160 mm | 160 mm | 160 mm | 160 mm | |

| Maximum Cycle Speed | 60 cycles (devir) / dk | 60 cycles (devir) / dk | 60 cycles (devir) / dk | 60 cycles ( evir) / dk | |

| Maximum Sheet Width | 1.120 mm | 940 mm | 1.120 mm | 940 mm | |

| Sheet Thickness | 0,1- 3,0 mm | 0,1- 3,0 mm | 0,1- 3,0 mm | 0,1- 3,0 mm | |

| Sheet Edge Heater Power | 3000 W | 3000 W | 3000 W | 3000 W | |

| Upper Resistance | 145 Kw | 125 Kw | 145 Kw | 125 Kw | |

| Lower Resistance | 145 Kw | 125 Kw | 145 Kw | 125 Kw | |

| Heaters Power | 290 Kw | 250 Kw | 290 Kw | 250 Kw | |

| Heating Tray Lenght | 2250 mm | 2500 mm | 2250 mm | 2500 mm | |

| Power Consumption | 45 - 80 Kw | 35 - 60 Kw | 40 - 70 Kw | 30 - 50 kW | |

| Vacuum Pump Capacity | 250 m3 | 250 m3 | 250 m3 | 250 m3 | |

| Clamping forces | Forming | 90.000 daN | 75.000 daN | 90.000 daN | 75.000 daN |

| Cutting | 90.000 daN | 75.000 daN | 90.000 daN | 75.000 daN | |

| Cooling Requirement | 30.000 Kcal/h | 30.000 Kcal/h | 30.000 Kcal/h | 30.000 Kcal/h | |

| Air Requirement ( 7 bar ) | 6-8 m3/ min. | 6-8 m3/ min. | 6-8 m3/ min. | 6-8 m3/ min. | |

| Dimensions of the Machines | Lenght | 9,65 m | 9,65 m | 8,60 m | 8,60 m |

| Widht | 3,00 m | 2,92 m | 3,00 m | 2,92 m | |

| Height | 3,20 m | 3,20 m | 3,20 m | 3,20 m | |

| Weight | 19.000 kg | 17.000 kg | 12,500 kg | 11.000 kg | |

| Control Unit | SEW EURODRIVE | ||||

Ideal For Large And Multi-Cavity Moulds

Design that allows precise cutting, especially in large and multi-cavity molds, with a maximum mold width of 1080 mm

Long-Lasting Chain Friendly

Long-lasting use of the chain thanks to specially designed chain rails and chain arms (chains last at least 2 times longer than average production times)

Advantage Of Installing High-Height Molds

Possibility of up to 160mm deep and high molds (Mold life is longer since the plug asist is in the servo center)

When The Servo Plug Is Active, The Mold Frame Is Also Active

Advantage of using mold frame at the same time in molds with servo plug

High Forming Efficiency

Easy forming in multi-cavity molds with a 2.5” high-pressure air-controlled MAC valve (Allows for higher cycle operation).

Easy Parallel Adjustment

With precise parallel adjustment, the risk of deviation in parallelism is minimal (0.02mm).

Long-lasting blade advantage in cutting blades with 0.02 mm minimum parallelism system.

Cutting And Stacking With Forward And Reverse Servo Motor And Screw Shaft

The back and forth positioning in the cutting and stacking stations is done with a servo motor and ball screw, which enables the positioning with a precision of 0.02 mm at the mold recipe values.

Powerful Cooling In The Cutting Station

Powerful cooling advantage with dual-way cooling input and output in the cutting station eliminates heating risk in blocks

2. 5 Tons Of Hydraulic Roll Lifting Power

Advantage of tying 2 x 2.5 tons of rolls.

Screen interfaces are designed to provide convenience to the user. Possibility of digital adjustment of machine forming air pressure via the monitor.

Gap Precision In Shears Is 0.03 mm

Gap precision of 0.03 mm in shears at cutting stations ensures rigidity in cutting. Clearance accuracy in scissors is 0.03 mm. The gap precision of the scissors at the cutting stations is 0.03 mm, which provides rigidity in cutting.

Mechanical components are manufactured in accordance with ISO tolerance standards.

FAG and SKF brands are used in the bearings.

The welding method applied at stations ensures longevity in presses. High standards of welding method are applied in the stations, ensuring long life in the presses.

All parts are manufactured with specially selected high qualified steels and special heat treatment processes.

The cooling system has a water flow warning with a flow switch.

With the special design to protect the vacuum system, the system gives a warning and any water leaks in the molds are removed from the system before they even reach the vacuum pump.

Namık Kemal Mah. 120. Sk. No:16 Esenyurt, İstanbul

Copyright © 2024 Omni Makina. All rights reserved. Design Sude Ajans

WhatsApp us